The rapid development of society has created an urgent need for energy, but also led to a series of environmental problems that endanger their own survival and development. Resolving the conflict between energy development and the environment is a great challenge facing the world today. Over the past few years, the Non-crystalline functional materials group has conducted a series of studies on the environmental and energy-related functional properties of aluminum-based amorphous alloys, hoping to add to this great cause. We have been working on two main fronts: first, developing aluminum-based amorphous alloys that can be used to clean up water pollution; and second, exploring aluminum-based amorphous alloys for energy applications such as energy storage and hydrogen precipitation. We have found that aluminum-based amorphous alloys have important applications as functional materials.

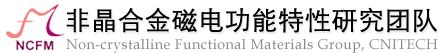

Organic wastewater such as printing and dyeing is an important source of industrial wastewater pollution. In recent years, colleagues at home and abroad have found that amorphous alloys based on Fe, Mg, and Co have excellent performance in degrading azo dyestuff solutions, and their fading rates can reach tens or even thousands of times that of the corresponding crystalline alloys. In our previous work, we introduced residual stress by ball milling method to improve the surface energy state of iron-based and magnesium-based amorphous alloy powders, which significantly improved their degradation activity of azo dyes, and the degradation rate of azo dyes reached 200 and 1000 times that of commercial iron powders, etc. 【Adv. Funct. Mater. 22, 2567 (2012); Sci. Rep. 2, 418 (2012); Materials China,33(5), 270 (2014)】 . However, in general the fading rate decreases rapidly with the increase of solution pH. Considering that many of the actual dye effluents are alkaline solutions, it is important to develop amorphous alloy systems that can fade rapidly in alkaline solutions to promote their applications. To solve this problem, our group, Pei-Pei Wang et al. found that aluminum-based amorphous alloys can rapidly degrade azo dyes over a wide pH range. Moreover, the degradation rates were 1.5 and 189 times faster in alkaline (pH=12) and acidic (pH=2) solutions than in neutral conditions. The study of the surface structure and elemental composition showed that elemental aluminum first undergoes de-alloying reactions and forms nickel- and yttrium-rich nanoporous layers on the surface, thus enhancing the effect of dye adsorption and accelerating the dye fading degradation process. These results suggest that aluminum-based amorphous alloys have promising applications in degrading alkaline, acidic and neutral dye effluents. The related results were published in J. Alloys Compounds 701, (2017) 759-767.

Figure I. Effect of Al-based amorphous alloy in degrading azo dye solution, solution concentration decay curve and surface morphology after reaction.

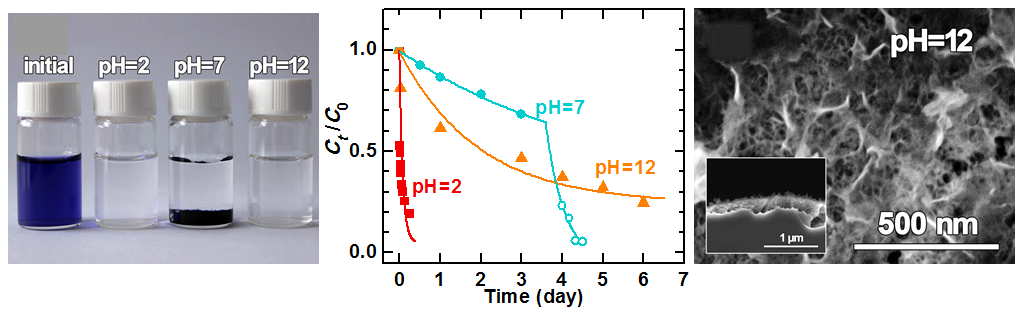

Nanoporous materials have attracted a lot of attention in many technical fields such as catalysis and energy storage due to their large specific surface area and adjustable composition. Based on the above work, Yang Hao and Yao Ayan in our group continued to study in depth the effects of alloy composition, crystallization organization structure and other factors on the dealloying of AlNiCo amorphous alloys to form nanoporous structures, and investigated their pseudocapacitance properties. Yang Hao found that the addition of 3 at.% Cu increased the specific capacitance of the nanoporous composites to 1.22 F cm2 and the work was published in J. Alloys Compounds 703, (2017) 461-465. Yao Ayan further designed a multi-stage nanoporous composite structure with triple dimensions by introducing a pre-crystallisation process, and the nanoporous scaffold also formed a metal/oxide core-shell composite structure, which substantially improved the ion and electron transport properties, with the final specific capacitance increasing to 3.35 F cm2, work published in J. Alloys Compounds 772, (2019) 164-172. Because of the good elasticity and high strength of Al-based amorphous alloys, this high energy storage density nanoporous material is expected to gain application as a flexible self-supporting supercapacitor electrode.

Figure 2. Demonstration of flexibility of aluminum-based amorphous alloy and comparison of pseudocapacitance characteristics of different nanomaterials in terms of multiplicity.

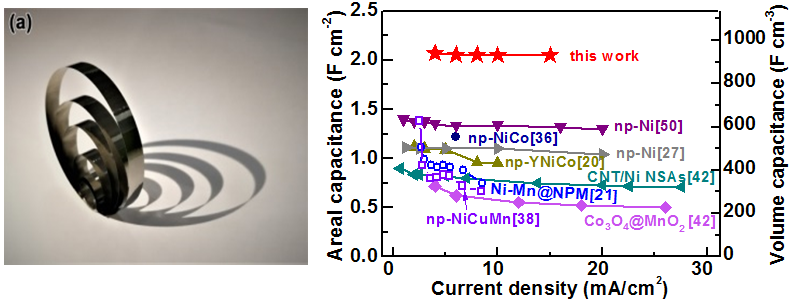

The most important feature of amorphous alloys as non-equilibrium materials is that different alloying elements can be added within a very wide range of compositions, which allows for multi-functionalisation of the material. Our group, Ju Song and Feng Jingqing, explored the development of high-performance active HER catalysts by using Al-based amorphous alloys as the substrate and adding small amounts of noble metal elements to control the material composition, and successfully developed Al80Ni6Co3Mn3Y5Au3 amorphous alloy materials, which were found to have a HER overpotential of about 70 mV @ 10 mA cm-2 and a Tafel slope of about 39 mV dec-1 in acidic environment, which can comparable to commercial noble metal Pt/C electrodes (33 mV @ 10 mA cm-2, 38 mV dec-1). Through microstructural and reaction mechanism studies, we found that this high catalytic activity can be attributed to the formation of the multicomponent high-entropy alloy nanoporous structure on the surface, where the synergistic effect of the homogeneously dispersed multiple elements results in very high hydrogen conversion frequencies and ion transport conductivity. The gold-rich protective layer formed at the interface during the reaction allows it to exhibit long-time stability, and the material also carries a very high yield strength, large elasticity and good electrical conductivity, making it an ideal free-standing catalytic electrode, with related work published in J. Mater. Chem. A 8, 3246 (2020).

Figure 3 Schematic view of the electrocatalytic HER of Al-based amorphous alloy strips and comparison of the performance of various electrode materials.

We can see that Al-based amorphous alloys are indeed a very interesting material, exhibiting multiple functional properties. It is believed that as the research progresses, more meaningful functional properties of Al-based amorphous alloys will be uncovered, and it is expected that amorphous alloys as a material will contribute to solving energy challenges and environmental issues.