Compared with crystalline alloys, amorphous alloys are non-equilibrium materials, which have disordered atomic structure, rich energy states, and can be relaxed through annealing treatment to obtain amorphous-nanocrystalline alloys in different states. Annealing relaxation can optimize its functional characteristics such as soft magnetic, catalytic, wear-resistant and anti-corrosion. Annealing mainly involves two important metastable characteristics: relaxation kinetics of amorphous alloys and crystallization of supercooled liquids. Clarification of the evolution law of relaxation mode in amorphous alloys, the crystallization mechanism of supercooled liquids and the relationship between the two is an important scientific prerequisite for comprehensive optimization of performance and promotion of their application.

Our non-crystalline functional materials group has long carried out in-depth and systematic research on the evolution of metastable characteristics of amorphous alloys and the mechanism of their influence on functional properties, and recently made a series of progress on the relaxation and crystallization laws during isothermal annealing of amorphous alloys.

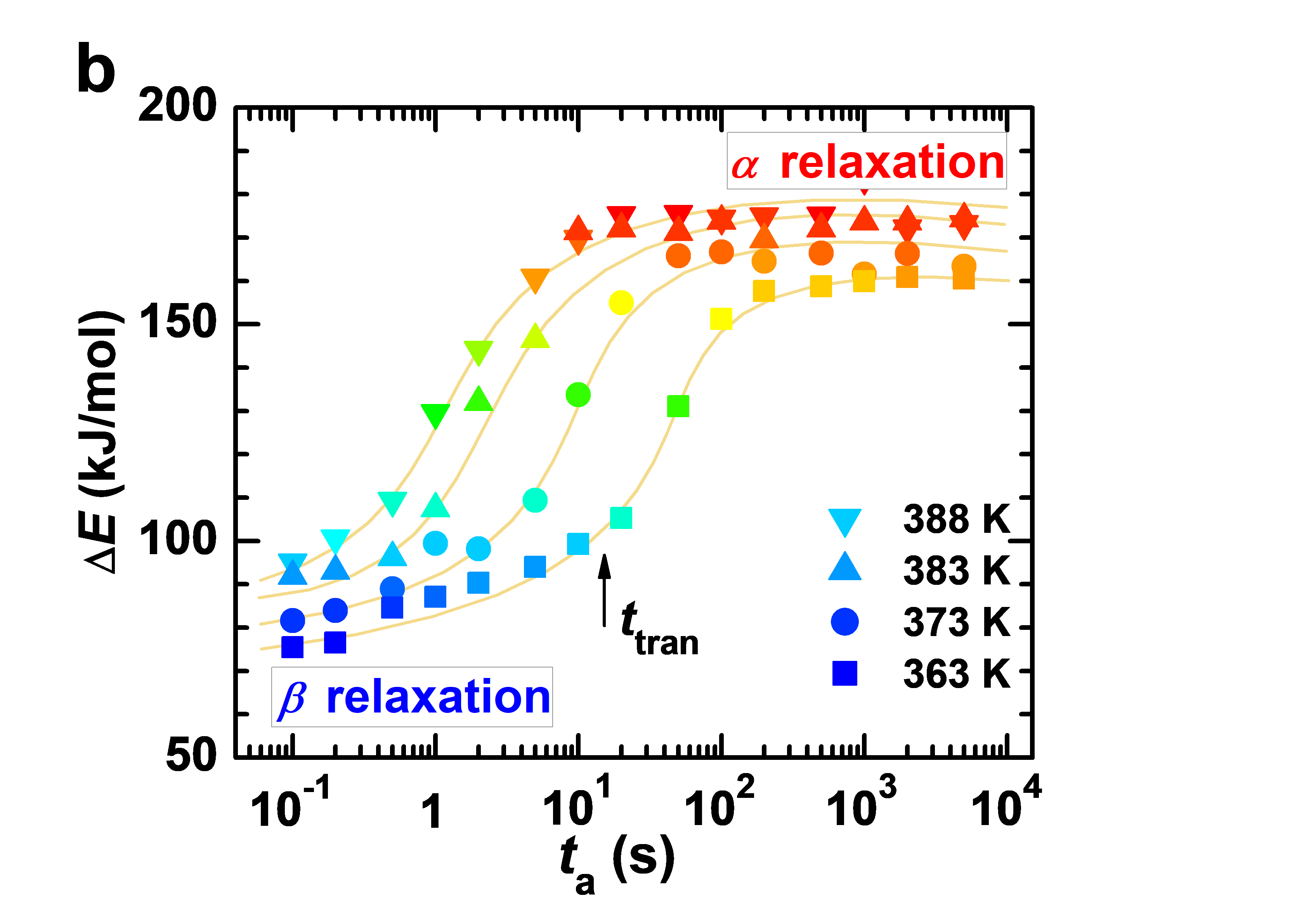

In order to clarify the relaxation kinetic process of amorphous alloys, we used high-precision Flash DSC to study the change of relaxation heat flow curve of a gold-based metal glass under isothermal annealing conditions, and found that the evolution of relaxation peak temperature (Tp) with annealing time is not a single law, but is divided into two stages: in the short-term annealing stage, Tp increases rapidly; As the annealing time increases, Tp enters a slow increase stage, as shown in Figure 1(a). By measuring the relaxation kinetic activation energy of these two stages, it is found that the activation energy of the first stage is small, which is in line with the generally β relaxation kinetic behavior, and the activation energy of the second stage is larger, which is in line with the generally α relaxation kinetic behavior. That is, low-temperature short-term annealing undergoes β relaxation, while high temperature triggers α relaxation for a long time, as shown in Figure 1(b). This result lays a theoretical foundation for the precise regulation of isothermal annealing process of amorphous alloys. This result was published in Intermetallics 93, 101–105 (2018).

Figure 1. (a) Two-dimensional contour map of the evolution of the relaxation heat flow peak of the gold-based amorphous alloy, and the relaxation peak temperature Tp (red solid sphere, marked by a solid yellow line) showing a two-step relaxation behavior; (b) The relaxation activation energy ∆E at different annealing times also showed a change from small to large.

As a non-equilibrium material, thermal stability is an important factor affecting the application of amorphous alloys. Glass transition temperature and energy state are important physical parameters to characterize the thermal stability of glass state, and based on the above work, we systematically study the influence of β relaxation and α relaxation on glass transition temperature and energy state. It can be seen that after Ta = 373 K isothermal annealing treatment, with the increase of annealing time ta, endothermic peaks appear near the glass transition temperature (Tg) and gradually move towards high temperature, as shown in Figure 2(a). According to the evolution law of relaxation enthalpy, it is found that the amorphous alloy undergoes three states during the annealing process: non-equilibrium glass state, metastable supercooled liquid equilibrium state and crystallization state. The optimal annealing path for the preparation of low-energy amorphous alloy is clarified: Ta = 274+ 132/log(ta), as shown in Figure 2(b). Based on the relationship between Tg and enthalpy, it is further found that α relaxation increases the thermodynamic stability (the lower the energy state, the more stable the glass thermodynamics) and the kinetic stability (the higher the glass transition temperature, the more stable the glass kinetics). The β relaxation makes the kinetic stability worse. These results provide theoretical guidance for understanding the relaxation behavior of amorphous alloys and improving thermal stability. This result was published in Acta Mater. 104, 25-32 (2016).

Figure 2. (a) the annealing heat flow curve of DSC of gold-based amorphous alloy changed with annealing time; (b) Two-dimensional contour plot of energy state (enthalpy) as a function of annealing temperature and annealing time. (c) The relationship between glass transition temperature and relaxation enthalpy.

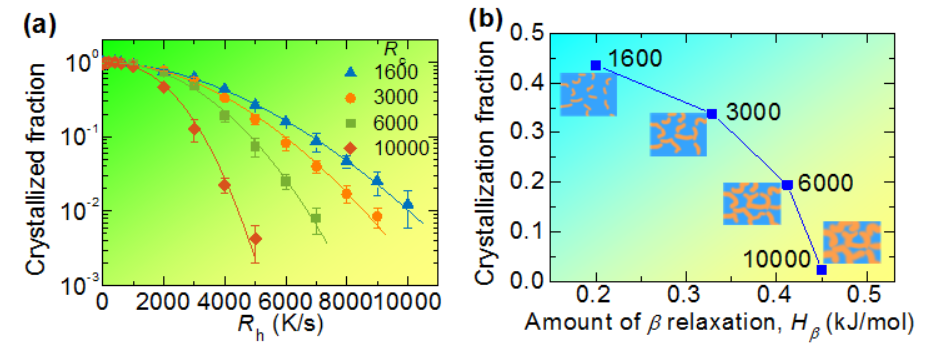

Crystallization is an important method to improve the properties of amorphous alloys, but the crystallization behavior is complex and the crystallization mechanism is still unclear. We further investigated the influence of the energy state and relaxation kinetics of amorphous alloys on crystallization behavior. By controlling the cooling rate and annealing, we prepare amorphous alloys with different energies, and the slower the cooling rate or the longer the annealing time, the lower the energy can be reduced. It was found that the higher the energy state of the amorphous alloy, the more difficult it is to crystallize during the heating process, as shown in Figure 3(a). Moreover, the energy changed by β relaxation has a more obvious effect on the crystallization nucleation, and the crystallization percentage of the sample increases with the decrease of the β relaxation content, as shown in Figure 3(b). This result shows that there is a coupling effect between the β relaxation of amorphous alloy and the crystallization nucleation of supercooled liquid, which is a new evidence of the genetic rule of amorphous to melt. It is proved that the precise regulation of the relaxation mode of amorphous alloy can increase the crystallization nucleation rate and refine the nanocrystalline grains, so as to optimize the production process of amorphous nanocrystalline. This result was published in Acta Mater. 185, 38-44 (2020).

Figure 3. (a) Evolution of crystallization percentage of gold-based amorphous alloys prepared at different cooling rates at different heating rates; (b) Relationship between crystallization percentage and β relaxation content.

The above works are supported by National Natural Science Foundation of China, the Zhejiang Provincial Natural Science Foundation of China and other projects.