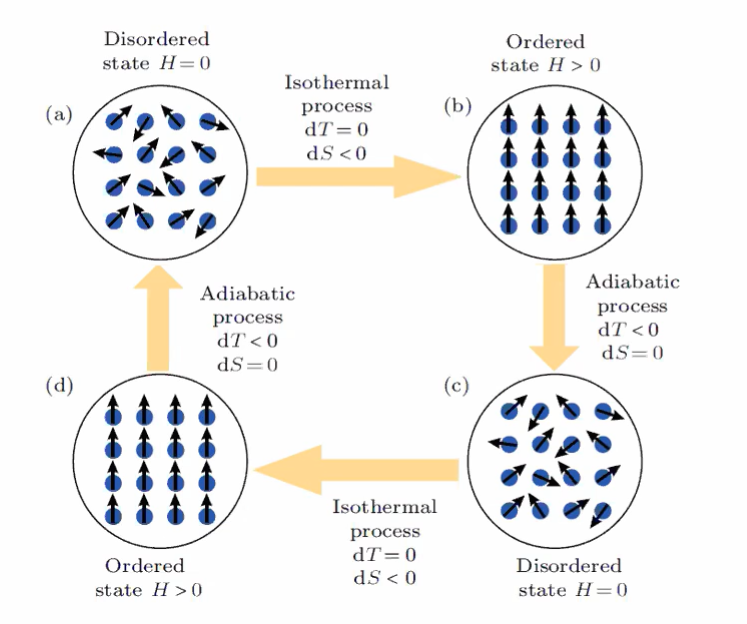

The magnetic refrigeration cycle based on the magnetocaloric effect (MCE), that is as an inherent nature for magnetic materials, expels and absorbs heat by magnetization and demagnetization processes, as shown in Fig. 1. The external magnetic field is equivalent to the compressor in traditional gas-compression refrigeration. Therefore, compared with traditional gas-compression refrigeration, the magnetic refrigeration has the advantages of high efficiency, low noise, compactness, environmental friendliness, working temperature range from low to near room temperature and wide range of application fields. In 2000, the United Nations issued the Montreal Protocol, which aims to (1) reduce the application of freon in the gas-compression refrigeration, (2) protect the ozone layer, (3) curb the increasing global warming effect, and (4) protect the living environment of human beings. The new magnetic refrigeration, as a potential substitute technology of the traditional refrigeration technology, has attracted a lot attention around the world.

Fig. 1 Schematic diagram of the isothermal and adiabatic process of the magnetocaloric effect in a magnetic system when the magnetic field is applied or removed. (a)→(b) or (c)→(d) isothermal process leading to the entropy change; (b)→(c) or (d)→(a) adiabatic process resulting in the temperature change.

Exploring the new MCE materials with high performance is the hotspot in the research area of magnetic refrigeration. The evaluation parameters for MCE materials are magnetic entropy change and refrigeration capacity (RC). The RC is calculated by  ×δTFWHM , where

×δTFWHM , where  is the peak of magnetic entropy change and δTFWHM is the full-width at half-maximum of the magnetocaloric curves (working temperature span). As the first-order magnetic transition materials, the conventional crystalline MCE materials, e.g., Gd5(Ge1-xSix), La(Fe1-xSix)13, exhibit the high

is the peak of magnetic entropy change and δTFWHM is the full-width at half-maximum of the magnetocaloric curves (working temperature span). As the first-order magnetic transition materials, the conventional crystalline MCE materials, e.g., Gd5(Ge1-xSix), La(Fe1-xSix)13, exhibit the high  near their Curie temperatures. However, the working temperature spans of this kind of materials are relatively narrow, leading to their decreased cooling efficiency. The amorphous alloys with a second-order phase transition exhibit unique advantage of wide working temperature span due to the disordered structure. This kind of materials attracted a lot of attention in recent years.

near their Curie temperatures. However, the working temperature spans of this kind of materials are relatively narrow, leading to their decreased cooling efficiency. The amorphous alloys with a second-order phase transition exhibit unique advantage of wide working temperature span due to the disordered structure. This kind of materials attracted a lot of attention in recent years.

A series of new MCE amorphous alloys and their microstructure have been studied by our Non-crystalline Functional Materials Group, Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences.

We obtained the rare-earth-based amorphous alloy with the highest magnetic entropy change among the rare-earth-based amorphous alloys until now, as shown in Fig. 2(a). The as-prepared Tm-based amorphous alloy exhibits the  of 18.3 J kg-1 k-1 under a magnetic field change of 5 T, which is similar with that of the giant magnetocaloric effect Gd5Ge2Si2 [J. Non-Crys. Solids. 2013 (359): 1]. We systematically investigated the magnetocaloric properties of Fe-based and Co-based amorphous alloys and obtained the mechanism for controlling their Curie temperatures and magnetic entropy change, as shown in Fig. 2(b) [J. Non-Crys. Solids. 2015 (425): 114; J. Magn. Magn. Mater. 2018 (446) 162; J. Magn. Magn. Mater. 2019 (475) 249; J. Magn. Magn. Mater. 2019(489) 165404].

of 18.3 J kg-1 k-1 under a magnetic field change of 5 T, which is similar with that of the giant magnetocaloric effect Gd5Ge2Si2 [J. Non-Crys. Solids. 2013 (359): 1]. We systematically investigated the magnetocaloric properties of Fe-based and Co-based amorphous alloys and obtained the mechanism for controlling their Curie temperatures and magnetic entropy change, as shown in Fig. 2(b) [J. Non-Crys. Solids. 2015 (425): 114; J. Magn. Magn. Mater. 2018 (446) 162; J. Magn. Magn. Mater. 2019 (475) 249; J. Magn. Magn. Mater. 2019(489) 165404].

Fig. 2 (a) The comparison for magnetocaloric effect between Tm-based amorphous alloys, the reported amorphous and crystalline MCE materials. (b) The magnetocaloric effect control of Fe-based amorphous alloys by rare-earth element.

We firstly induced the compositional design method of high-entropy alloy in the rare-earth-based amorphous alloy. We explored a series of high-entropy metallic-glasses with high magnetocaloric properties. All explored high-entropy metallic-glasses exhibit the relatively high  and RC. The highest

and RC. The highest  and RC are up to 15 J kg-1 K-1 and 691 J kg-1, respectively. We found that the wide working temperature span of the high-entropy metallic-glass is attributed to its spin-glass phase and complex structure. The highest value of working temperature span is up to 116 K. The wide working temperature spans leads to the high RC of high-entropy metallic-glasses. In addition, by changing the alloyed rare-earth and ferromagnetic transition metal elements, we successfully controlled the glass forming ability, transition temperature, magnetocaloric response and cooling efficiency of high-entropy metallic-glasses. The related literatures are J. Alloys Compd. 2019 (776) 202-206; Intermetallics, 2015 (58): 31-35 and J. Appl. Phys. 2015 (117): 073902. The related patents are 201811227003.3; 201410310509.6, which have been transferred to Ningbo Zhongke B Plus New Material Technology Co., LTD.

and RC are up to 15 J kg-1 K-1 and 691 J kg-1, respectively. We found that the wide working temperature span of the high-entropy metallic-glass is attributed to its spin-glass phase and complex structure. The highest value of working temperature span is up to 116 K. The wide working temperature spans leads to the high RC of high-entropy metallic-glasses. In addition, by changing the alloyed rare-earth and ferromagnetic transition metal elements, we successfully controlled the glass forming ability, transition temperature, magnetocaloric response and cooling efficiency of high-entropy metallic-glasses. The related literatures are J. Alloys Compd. 2019 (776) 202-206; Intermetallics, 2015 (58): 31-35 and J. Appl. Phys. 2015 (117): 073902. The related patents are 201811227003.3; 201410310509.6, which have been transferred to Ningbo Zhongke B Plus New Material Technology Co., LTD.

Fig. 3 The effect of temperature, magnetic field and rare-earth element on the magnetocaloric responses of the high-entropy metallic-glasses.

The high surface-to-volume ratio of the microwire satisfies the demand for high heat-exchange efficiency of practical magnetic refrigeration. However, the most rare-earth based alloy microwires are hard to be prepared which is attributed to the fragile nature of the most rare-earth based alloys. Aiming to solve this problem, we used the melt-extraction equipment to prepare the rare-earth containing high-entropy metallic-glass microwires [Intermetallics 2018 (96) 79], amorphous composite microwires [201911301937.1] and crystalline microwires [201510106273.9; 201811101568.7]. Our microwires simultaneously possess the large magnetocaloric properties and the optimal shape needed by the practical application. Therefore, in the research field of magnetic refrigeration, especially in the field of the high frequency magnetic refrigerator, our microwires own the great application prospect.

Fig. 4 (a) The schematic illustration of melt extraction technique, (b) the optical image, and (c), (d) the SEM images of high-entropy metallic-glass microwires.

The above research work has been supported by the projects of the National Natural Science Foundation of China, the Natural Science Foundation of Zhejiang Province, the Natural Science Foundation of Ningbo City, the Project funded by China Postdoctoral Science Foundation, and the Youth Innovation Promotion Association of the Chinese Academy of Sciences.