Owing to its special disordered atomic structure and alloy composition, iron-based amorphous alloys exhibit excellent soft magnetic properties, and has broad application prospects in transformers, motors, sensors and other power electronic devices, which is an important energy-saving, green and environmentally friendly new material. The preparation of amorphous alloys requires inhibition of crystal growth, rapid cooling of the metal melt to less than half of the melting temperature (if the crystal does not have time to nucleate and grow, the disordered atomic structure of the melt will be frozen to form amorphous). The rapid cooling process significantly shortens the production preparation process and improves production efficiency. However, the non-equilibrium solidification process freezes severe internal stresses, and the soft magnetic properties of cast amorphous alloys are not very good due to magnetoelastic coupling. The effect of stress can be effectively reduced by annealing relaxation, but it tends to make amorphous alloys brittle. The annealing process mainly uses the relaxation to regulate the properties of amorphous alloys, but there are abundant relaxation phenomena in amorphous alloys, and there is also coupling between different relaxation modes. The precise regulation of different relaxation modes and the clarification of the influence of different relaxation modes on the properties are expected to improve the magnetic properties while maintaining the good mechanical properties of amorphous alloys, which is of great significance for its application.

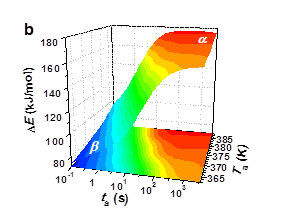

Under the guidance of researcher Junqiang Wang and Associate Professor Juntao Huo, Lijian Song, Nana He and Su Ouyang from the non-crystalline functional materials group of the Magnetics Division of Ningbo Institute of Materials of the Chinese Academy of Sciences conducted in-depth research on the isothermal relaxation behavior of amorphous alloys and their influence on magnetic properties and microscopic mechanisms. Firstly, the relaxation kinetic behavior of different alloy systems under isothermal annealing treatment was systematically studied by using a flash scanning calorimeter with high precision and ultrafast heating/cooling rate. It was found that the isothermal annealing process was not a single relaxation mode, but a transition process from β relaxation to α relaxation (Figure 1). That is, when the low temperature is annealed for a short time, the amorphous alloy undergoes a β relaxation stage, and when the annealing temperature is high enough or the annealing time is long enough, the α relaxation behavior will be triggered. This isothermal transition process is caused by the annihilation of the free volume of the loosely arranged region to enhance the coordinated motion of atoms. These results show that the precise regulation of different relaxation modes in amorphous alloys can be realized. Related articles were published in Intermetallics 93, 101–105 (2018).

Fig. 1. The relaxation activation energy has a transition process from β relaxation to α relaxation with the evolution of annealing temperature and annealing time.

Furthermore, by accurately controlling the relaxation mode in iron-based amorphous alloys, we studied the effects of different relaxation modes on the soft magnetic functional properties and mechanical deformation ability of iron-based amorphous alloys. It was found that there were significant differences in the influence of different relaxation modes on the soft magnetic properties of iron-based amorphous alloys. β relaxation stage can effectively improve the soft magnetic properties, the coercivity is significantly reduced, and the magnetic permeability is significantly increased, while maintaining good mechanical properties. The α relaxation stage has no obvious effect on the soft magnetic properties, and the coercivity and magnetic permeability remain basically unchanged, but the mechanical deformation ability deteriorates, and the amorphous alloy becomes brittle (Figure 2). The above work shows that the influence of different relaxation modes on different properties of amorphous alloys is different, and by accurately controlling the relaxation mode in amorphous alloys, the incompatibility problem between different properties can be solved and the comprehensive performance can be improved, and these results are of great significance for improving the processing technology of soft magnetic amorphous alloys. Related work is being sorted out and submitted, and a national invention patent has been applied (201810310296.5).

Fig. 2. The evolution of relaxation activation energy, soft magnetic properties and deformation capacity with annealing time during isothermal annealing.

To further investigate the microscopic mechanism by which β relaxation affects soft magnetic properties, our group investigated the coupling between domain motion and structural inhomogeneity. Since stress activates β relaxation, they introduced a stress gradient field by nanoindentation and found that the affected area of stress on the magnetic domain increases in proportion to the increase of indentation depth. Due to the magnetoelastic coupling, the domain wall is arranged along the contour line of the stress gradient field, and the radius of the magnetic domain distortion region is about 7.9 times the indentation size. By studying the motion of the magnetic domain wall in this region under the applied magnetic field in situ (Figure 3), it is found that the magnetization of the amorphous alloy is determined by the movement of the magnetic domain wall. The closer to the nanoindentation, the more difficult it is for the domain wall to move, meaning the lower the permeability.

Fig. 3, (a-h) Changes in the domain structure around the nanoindentation under the applied magnetic field; (i) The variation of magnetic domain wall movement capacity with distance from nanoindentation.

In order to quantitatively characterize the residual stress around the nanoindentation, we used amplitude-modulated atomic force microscopy (AM-AFM) to study the microstructure and mechanical properties around the indentation (Figure 4). Since the atomic structure of amorphous alloy is in a disordered state, its dynamic mechanical properties show viscoelastic behavior. And the closer to the indentation, the greater the viscosity loss energy, which is related to the shear deformation mechanism in amorphous alloys. In order to study the quantitative relationship between stress and viscous loss, the viscoelastic structure in the tensile state was further studied in situ, and it was found that there was a linear relationship between external stress and viscous loss energy.

Fig. 4. Study of viscoelastic inhomogeneity structure at different locations near nanoindentation, and the color change represents the viscoelastic loss energy in kinetic measurement.

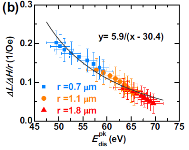

Based on the above experimental results, we found that there is a clear correlation between the domain wall movement ability and the viscoelastic loss energy (Figure 5), and it can be fitted by the magnetoelastic coupling theory, and the fitting results show that the magnetic domain wall thickness in the soft magnetic amorphous alloy is about 36 nm, which is similar to the characteristic scale of viscoelastic ratio uniformity.

These results show that the viscoelastic inhomogeneity structure at the nanoscale is an important sequence parameter for characterizing the stress state and magnetoelastic coupling strength of amorphous alloys, and regulating the viscoelastic inhomogeneity will become a new method to improve the soft magnetic properties of amorphous alloys. The results were published in Phys. Rev. Materials 2, 063601 (2018).

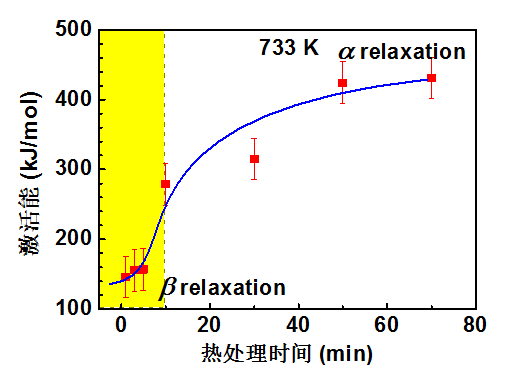

Fig. 5 (a) The relationship between the movement capacity of the domain wall around the indentation of different sizes and the viscous loss energy; (b) The correlation law between the moving capacity of the reduced magnetic domain wall and the viscous loss energy and the theoretical fitting results of the magnetoelastic coupling effect.

The above works are supported by National Natural Science Foundation of China, the Zhejiang Provincial Natural Science Foundation of China and The National Key Research and Development Program of China.