Iron-based amorphous alloy has excellent soft magnetic properties and has a wide application prospect in electromagnetic devices such as transformers, reactors, magnetic amplifiers, and switching power supplies. However, the soft magnetic properties of quenched iron-based amorphous alloys are not good, such as large coercivity and low magnetic permeability. This is mainly due to the internal stress in the quenched iron-based amorphous alloy, and the magnetoelastic coupling effect makes the soft magnetic properties worse. In order to improve the soft magnetic properties of iron-based amorphous alloys, it is necessary to reduce or eliminate the internal stress in the sample. At present, the soft magnetic properties are mainly improved by annealing around the transition temperature of the glass to accelerate atomic relaxation and reduce internal stress. However, annealing treatment will deteriorate the mechanical properties, resulting in brittle amorphous alloys, which makes the strip processing properties and device stability worse. How to improve the magnetic properties while maintaining good mechanical properties is of great significance to the application of amorphous alloys.

The annealing process mainly uses the relaxation phenomenon to control the properties of amorphous alloys, but there are abundant relaxation phenomena and model coupling in amorphous alloys. How to achieve the precise regulation of different relaxation modes is of great significance to understand the influence of different relaxation modes on performance.

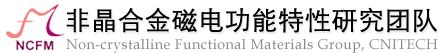

Recently, under the guidance of Wang Junqiang and Huo Juntao, Song Lijian and He Nana from the non-crystalline functional materials group of the Magnetics Division of Ningbo Institute of Materials of the Chinese Academy of Sciences systematically studied the relaxation kinetic behavior of different alloy systems under isothermal annealing treatment conditions by using a flash scanning calorimeter with high precision and ultra-fast heating rate. It is found that the isothermal annealing process is not a single relaxation mode, but there is a transition process from β relaxation to α relaxation, as shown in Figure 1. That is, when the low temperature is annealed for a short time, the amorphous alloy undergoes a β relaxation stage, and when the annealing temperature is high enough or the annealing time is long enough, the α relaxation behavior will be triggered. This isothermal transition process is caused by the annihilation of the free volume of the loosely arranged region to enhance the coordinated motion of atoms. These results show that the precise regulation of different relaxation modes in amorphous alloys can be realized.

Fig. 1. The activation of relaxation can change from β relaxation to α relaxation with the evolution of annealing temperature and annealing time

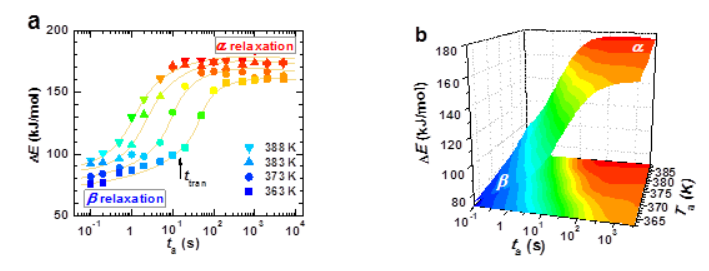

Furthermore, by accurately controlling the relaxation mode in iron-based amorphous alloys, we studied the effects of different relaxation modes on the soft magnetic functional properties and mechanical deformation ability of iron-based amorphous alloys. It was found that there were significant differences in the influence of different relaxation modes on the soft magnetic properties of iron-based amorphous alloys. β relaxation stage can effectively improve the soft magnetic properties, the coercivity is significantly reduced, and the magnetic permeability is significantly increased, while maintaining good mechanical properties. The α relaxation stage has no obvious effect on the soft magnetic properties, and the coercivity and magnetic permeability remain basically unchanged, but the mechanical deformation ability becomes worse and the amorphous alloy becomes brittle, see Figure 2. It shows that by precisely adjusting the relaxation mode in amorphous alloys, the soft magnetic properties can be improved without deteriorating the mechanical properties.

Fig. 2 The evolution of relaxation activation energy, soft magnetic properties and deformation capacity with annealing time during isothermal annealing.

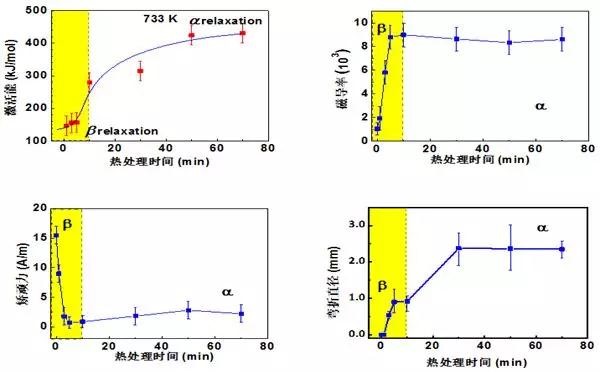

Fig. 3 The relaxation activation energy of iron-based amorphous alloy changes with temperature and time, and the marked heat treatment zone means the improvement of comprehensive performance.

The above work shows that the influence of different relaxation modes on different properties of amorphous alloys is different, and by accurately controlling the relaxation mode in amorphous alloys, the incompatibility problem between different properties can be solved and the comprehensive performance can be improved, and these results are of great significance for improving the processing technology of soft magnetic amorphous alloys. The relevant results were published in Intermetallics, 93, 101 (2018), and applied for a national invention patent (201810310296.5).