Researchers at the Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, have harnessed artificial intelligence to develop a series of Fe-based amorphous alloys featuring both ultra-high magnetization and ultra-low coercivity. These materials promise to boost the energy efficiency and performance of high-frequency, high-power electronic devices. The study was published in Advanced Functional Materials (DOI: 10.1002/adfm.202425588).

As modern electronics demand higher operating frequencies—reaching into the MHz and GHz ranges—traditional soft magnetic materials like silicon steel face significant challenges. These materials exhibit escalating core losses, reducing system efficiency, increasing heat generation, and risking thermal runaway. This inefficiency hampers critical applications such as 5G communication, electric vehicles, and industrial power supplies, where compact, lightweight, and efficient systems are essential.

Fe-based amorphous alloys are regarded as next-generation soft magnetic alloys with immense potential, delivering low coercivity Hc (typically below 10 A/m) and reduced core losses compared to silicon steel. However, their saturation magnetization (Bs), ranging from 1.2 to 1.7 T, falls short of silicon steel’s 1.8–2.0 T, limiting their use in high-power-density devices. Historically, the absence of a clear theoretical link between composition and properties has forced reliance on trial-and-error methods, slowing progress in alloy development.

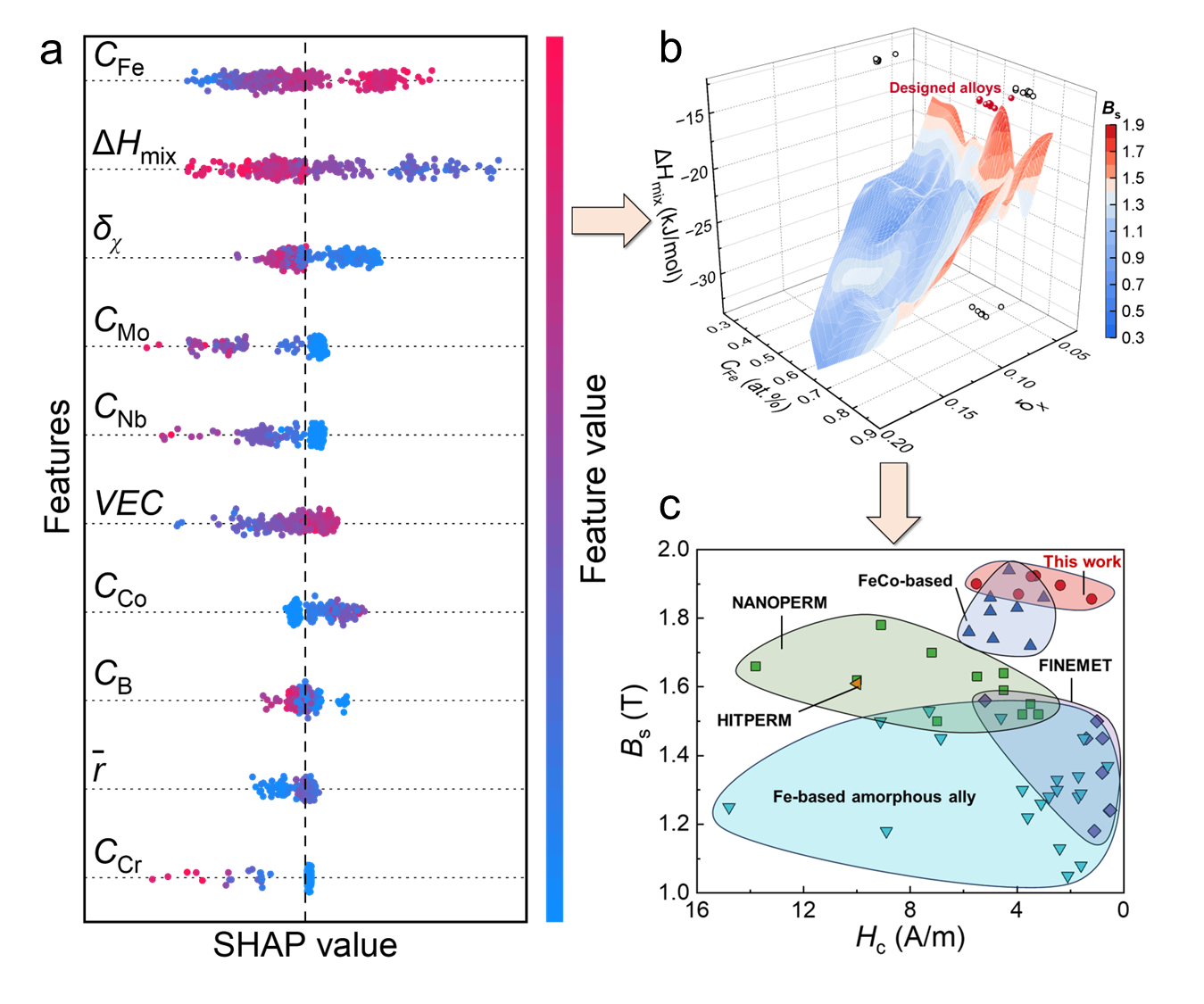

To overcome these hurdles, the research team employed machine learning models to predict and optimize the Bs of Fe-based amorphous alloys. The XGBoost model excelled, achieving an R² coefficient above 0.85 and a root-mean-square error below 0.12 T. Through feature analysis, the team identified iron content (above 75 atomic percent), mixing enthalpy (-18.7 to -14 kJ/mol), and electronegativity difference (below 0.07) as key factors driving high Bs while preserving glass-forming ability.

Guided by these insights, the researchers incorporated cobalt to leverage the Fe-Co exchange coupling effect, designing alloys like Fe-Co-Ni-Si-B and Fe-Co-Ni-B-P-C. After magnetic field annealing, these alloys achieved Bs values exceeding 1.85 T, some reaching 1.92 T, and Hc as low as 1.2 A/m, surpassing silicon steel’s performance across both metrics.

These advanced alloys promise to enhance energy efficiency, reduce energy losses, and enable smaller, lighter magnetic components in electronic systems. Their properties position them as ideal candidates for next-generation technologies requiring high power density and minimal waste heat.

The study was led by Prof. Junqiang Wang and Dr. Juntao Huo, with Shiyu Yang as the first author. This work was supported by the National Key R&D Program of China (2024YFB3813700), the National Natural Science Foundation of China (52231006, 52001319, 92163108, 52271158, 52222105, 51827801, 52201194), the Zhejiang Provincial Natural Science Foundation (LGF22E010002, LZ22A030001, LR22E010004), the Pioneer, Leading Goose” R&D Program of Zhejiang (2022C01023), and the Ningbo Key Scientific, Technological Project (2019B10051).

Fig . Development of high Bs Fe-based amorphous alloys based on machine learning-derived alloy design criteria. (a) SHAP value distribution of alloy features. (b) Distribution of Bs in the CFe -ΔHmix-δχ space. (c) Comparison of Bs and Hc for different types of Fe-based amorphous/nanocrystalline alloys.

WANG Junqiang

Ningbo Institute of Materials Technology and Engineering

E-mail: jqwang@nimte.ac.cn